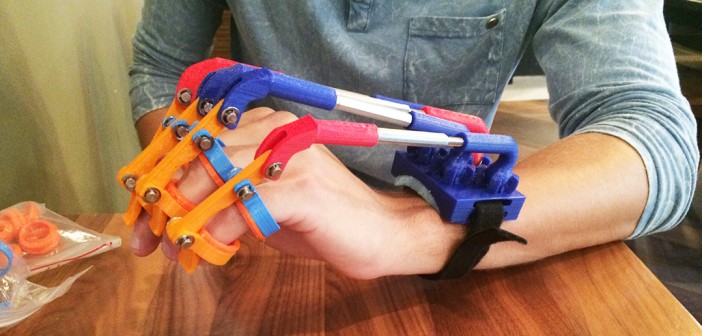

In the medical world, prosthetic hands can cost a patient thousands of dollars, but a group of Lehigh students set out to change that with their Mountaintop project that developed 3-D printed exoskeletons over the course of two summers.

Daniel Levy, ’16, one of the students involved in the project said that by 3-D printing these exoskeletons, the team could save patients hundreds of dollars, seeing as they could make one for around $20.

When they developed this project, one thing the team quickly agreed upon was that their model had to have the capability to be easily 3-D printed at the convenience of someone’s home.

“We wanted to keep away from electrical parts to ensure potential clients will be able to print the exoskeleton at their convenience,” Levy said.

The group — Levy; Emily Macmillan, ’16; Elena Ramirez, ’15; and Jeff Peisner, ’15 — has made several advances and furthered its research over the past two summers in working with and designing exoskeleton appliances. The students’ designs will “aid in the rehabilitation for patients with muscle disorders of the hand,” according to the Mountaintop website.

“Our overarching challenge was to translate wrist motion into movement in one’s fingers,” Levy said.

With a clear goal in mind involving 3-D printed exoskeletons, the group’s Mountaintop project proposal was quickly approved and the students were able to delve right into their research.

The team obtained a partnership with Good Shepherd Rehab, a rehabilitation center based in Allentown, and have met with the facility’s hand therapist to receive feedback on their exoskeleton models.

“At the start of the summer we visited (Good Shepherd) and realized that not many kids needed prosthetic hands,” Ramirez said. “It was a great cause, but the market wasn’t there. (Good Shepherd) showed us their exoskeletons and after watching a YouTube video of a doctor who made a young girl 3D printed exoskeleton arms, we switched directions and the project took off from there.”

Instead of focusing on prosthetic hands, the students built off of the idea of neuroplasticity, which will allow patients to make new connections in their brain in order to regain hand motion. With the exoskeletons, patients will be able to work on their hand motion at their own convenience, unlike in therapy.

Each student on the team created his or her own model for the project. The goal of each design was to induce neuroplasticity in stroke survivors.

“With each design we wanted to recreate a movement so survivors could relearn a hand or arm movement,” Ramirez said.

Each student was responsible for a different movement. Ramirez worked to open the hand, Peisner and Levy worked to close the hand and Macmillan helped to close the elbow. The students worked with a code to measure the joints from a photo of the hand. The measurements were used for all four designs.

The four fictional prototypes were uploaded to Thingiverse, a website for open source sharing of 3D models. Ramirez said Thingiverse allowed the team to share its software to the public, so anyone can make and use its designs.

The team believes that it has benefited from having started work on the project last summer. Working an additional summer allowed the students to expand on their ideas.

The team credits its success in part to its mentors, who include Marc de Vinck of the Baker Institute, Lisa Getzler of the Baker Institute and John Grencer of Good Shepherd Rehabilitation Hospital.

“Getzler was key in navigating the team through the logistics of doing a biomedical project,” Ramirez said. “There are a lot of legalities when you get close to patients and she grounded us by teaching us these processes.”

Professor Christina Haden advised the team last year, and Ramirez says she instilled in her the confidence to pursue the project by helping in the creation of an encouraging group dynamic where members of the team fostered their individual talents together.

In addition, Ramirez said that William Best, a mechanical engineering professor, was a key helper due to his patient-conscious engineering advice during the designing process.

Best feels that his greatest contribution to the group was asking questions that they may not have thought about.

“I would ask them if they think the design will work, not only logistically, but aesthetically. Would children want to wear this? I encouraged the students to think about the design from a psychological perspective,” he said.

Best believes that this unique experience is able to happen because of the incredible quality of the students involved.

“With a project as potentially life changing as this, I’d love to see it continue,” he said.

Comment policy

Comments posted to The Brown and White website are reviewed by a moderator before being approved. Incendiary speech or harassing language, including comments targeted at individuals, may be deemed unacceptable and not published. Spam and other soliciting will also be declined.

The Brown and White also reserves the right to not publish entirely anonymous comments.

4 Comments

I actually developed a fake hand with my 3D Printer (http://3dprinterreviewsite.com/hictop-prusa-i3-3d-desktop-printer-review/). It’s getting to the point where you can pretty much make anything these days, putting out the use for manufacturers.

Hi there, that 3d printed exoskeletons or whatever you called it was very awesome. I think this is what will happen when technology meets with creativity. We should apprciate th student who made this idea becomes true.

Thank you

Desy from http://www.techcommjournal.org

That was something we must appreciate For a student has already had an idea like this is really cool thing. I think this is what happen if a technology meets with creativity. Thanks for a very nice share mate.

Regards,

Erdi from http://www.techcommjournal.org

Hi there!

Thank you for sharing this nice post to the world. I think we should appreciate this student creativity. For a 16 year’s old student to make this 3d printed exoskeletons is really cool.