Nestled in the back halls of Chandler-Ullmann, Lehigh’s design labs provide technical resources for a range of disciplines and students.

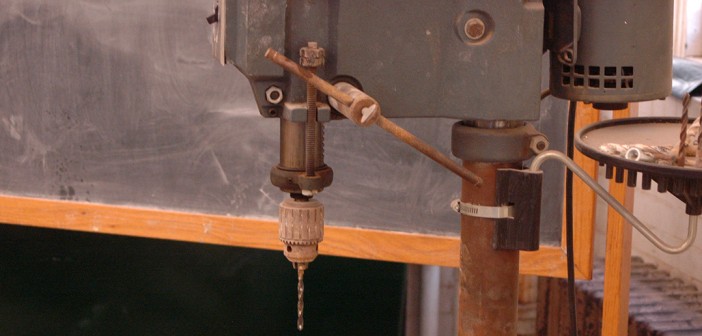

The design labs include popular tools such as the woodshop, a CNC router and a laser cutter supervised by managers Brian Slocum, Michael Moore and student shop managers. An extension of the design labs is the metal shop located in Wilbur Powerhouse.

While there are many resources made available to students, sometimes these can be stretched thin at high-traffic times of the semester. Students in mechanical engineering, electrical engineering, the technical entrepreneurship program, the integrated product development program, product design, graphic design, architecture and sometimes even sculpture are all in disciplines that may have need for the labs’ resources in one way or another.

Lucy Gans, a professor and chair in art and architecture, said while the design labs are housed in their department, the intention is not for them to be exclusively for one set of students or one program.

“The idea behind the design labs is that it would be a kind of hub and a kind of design center for the university and that it would be managed by our staff,” Gans said.

In the Design 004 class, students are taught to use the program AutoCAD, which is used to draw patterns to be cut by the laser cutter. Students send their file to an email address to be put in the queue to get cut and then put their materials in drawers outside the lab. The queue works such that the files are cut in the order in which they are emailed.

“I think the labs are a great resource, but sometimes the hours are kind of limiting when they’re open,” said Liz Phillips, ‘16, a design student who uses the laser cutter for her projects.

She said sometimes the queue gets longer when a lot of students need materials at the same time because a project deadline is coming up. It can be difficult to plan ahead and get files in as early as possible, she said.

“(The laser cutter) is kind of an option, but it’s still a really good resource and our teachers encourage us to use it,” she said.

Moore, the assistant manager of the design labs, is involved in the organization of work study students to monitor the several parts of the labs.

“Typically we try to have two or three of them working at a time, so that one of them, during slow times, can come over and run the laser cutter,” Moore said.

This semester the design labs have 21 work study students, which Moore said is a bit lighter than their typical staff.

“In the past we’ve usually tried to keep it around 24 to 25,” he said. “The reason for that is the woodshop open hours primarily.”

The labs are open 9 a.m. to noon, 1 to 4 p.m. and 5 to 9 p.m. on weekdays. Some classes reserve the wood shop. The labs are closed from Friday night through to Sunday morning, according to Moore.

Chester Toye, ‘17, has created his own major of urban planning, which includes him taking architecture classes and using resources such as the laser cutter.

“I personally haven’t had any issues,” he said. “Sometimes it gets a bit backed up or it might be understaffed and it probably could’ve got cut quicker but there was never a time crunch.”

Toye suggested more student training and more monitors could help the process move faster during times of high traffic.

The shop monitors are recruited from the work study fair at the beginning of the year as well as design classes. Once recruited, shop monitors receive eight hours of training for the woodshop – the most-used resource, according to Moore.

After that, Moore said they leave it open as to whether or not the shop monitors want to learn how to use the laser cutter. Shop monitors receive a small bump in pay once they are trained to use it, Moore said.

Training for the laser cutter entails an hour of one-on-one training with an experienced staff member and then one to two hours of supervised cutting with Moore or Slocum.

“Some of my friends had to pull all-nighters or drive to Northampton just because their material wasn’t cut until super late,” Toye said. “But it’s definitely tough with the amount of people they had in that class.”

He explained an experience of his own, where he submitted his file at night and it was cut by the next afternoon.

The industrial grade laser cutter requires student staffing because it is more difficult to use. But the design labs will be getting two new, smaller laser cutters next year from a company called Glowforge. According to Moore, these machines are smaller and have less power, but the ease of use is far beyond the industrial machine.

This will result in more direct access for students on a first-come, first-serve basis to print to these machines and cut it themselves, while still having a staff member or monitor watching.

“We totally understand that there definitely is kind of a gap there and hopefully the two new machines that we’re getting will help to fill that,” Moore said.

Gans said the department has an equipment budget to buy and service new equipment.

“Most of the time we try the best we can to keep up with student demand, so that’s our first priority to make sure that things go smoothly,” Gans said.

Although the department is working to increase its technical resources, Moore also said that sometimes it can be faster and more efficient to cut things by hand.

“I think it’s a fantastic resource, but at the same time I kind of agree with some of the architecture professors that I think it’s overused and students come to depend on it in a way that they really don’t have to,” he said.

Phillips said she tries do a lot of handwork, but the laser cutter tends to look nicer. She said that students may sometimes overuse the laser cutter for things that they could do by hand due to its precision.

Gans believes the faculty that use the laser cutter and assign work on it would be clear about problems or how to work things out, because otherwise their students wouldn’t be able to get their work done in time.

“I think they really want to have the resources be available for students and be as efficient as possible,” Toye said.

Comment policy

Comments posted to The Brown and White website are reviewed by a moderator before being approved. Incendiary speech or harassing language, including comments targeted at individuals, may be deemed unacceptable and not published. Spam and other soliciting will also be declined.

The Brown and White also reserves the right to not publish entirely anonymous comments.