Upon opening the door to Wilbur Powerhouse, an unadorned gray stone building near the bottom of Lehigh’s campus, the first sound that greets a visitor’s senses is a low mechanical hum — the sound of dozens of 3-D printing machines running, simultaneously sucking up electricity from the powerhouse.

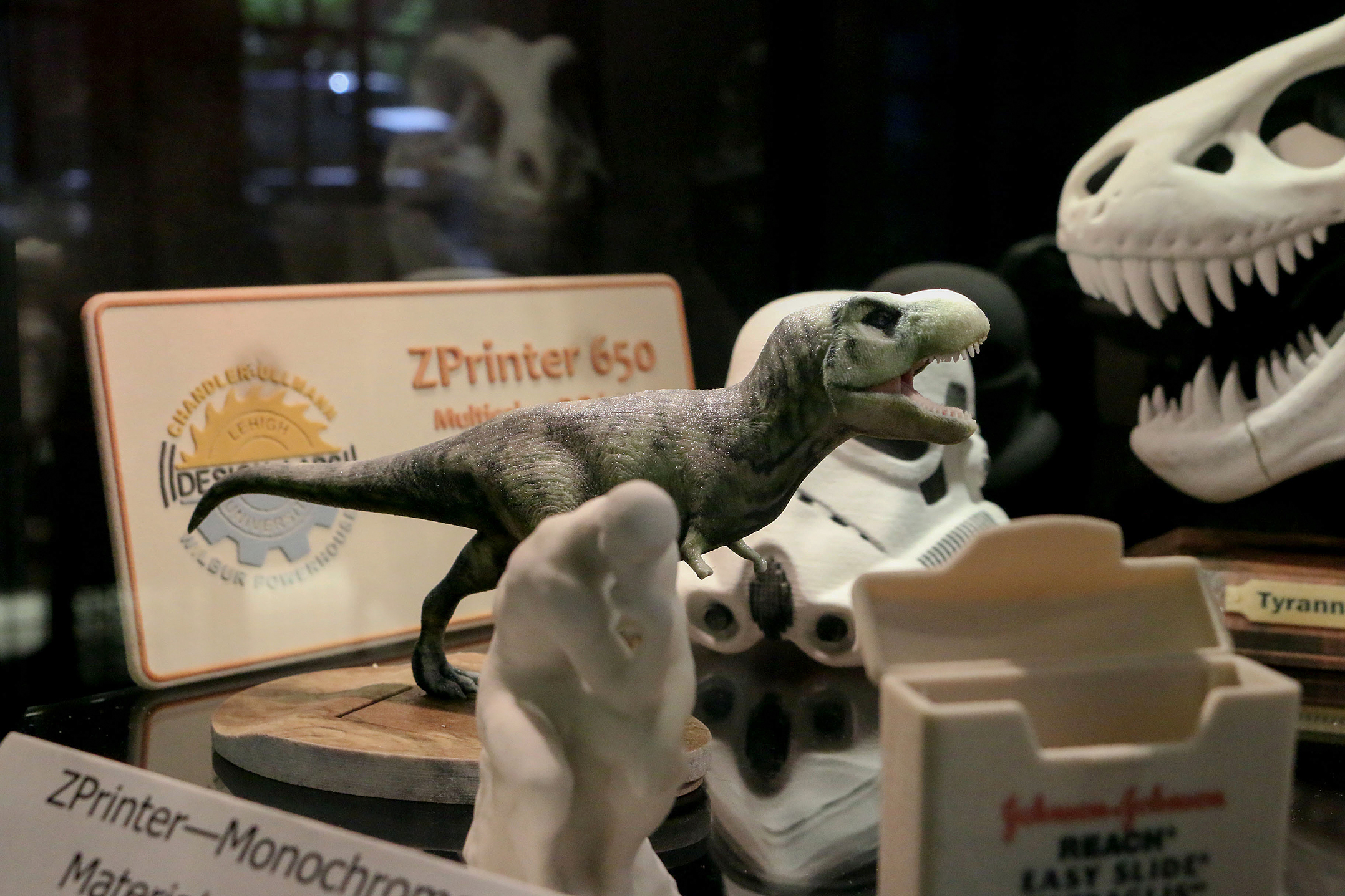

A colorful display of samples from the 3-D printers is arranged artfully at the front desk. There are figurines hardly bigger than a coin, bright strands twisted together into artistic shapes and a foot-tall, rainbow-colored model of the Eiffel Tower, among other things.

The variety of the pieces draws the visitor farther in, where closer inspection reveals their intricate compositions. Some are made up of loops of plastic and tiny links that only appear delicate, while others look solid enough to have come right out of a factory mold.

All of this is a lead-up to the main attraction: rows and rows of pristine white 3-D printers, some humming softly as they spin out new creations while the rest lay dormant. And beside them, in a separate glass room like a trophy on display, is the pride and joy of Wilbur: the new Renshaw metal 3-D printer.

The first 3-D printer had already been at Lehigh for some time when graduate student and lab manager Trevor Verdonik started working there. Verdonik, who witnessed the entire creation of Wilbur’s 3-D lab, said once the movement toward 3-D printing started, it picked up speed fast.

“We said, let’s try getting some of these less expensive printers and maybe we’ll try putting one out for student use and see what happens,” Verdonik said. “Well, the next thing we knew it was being used 24 hours around the clock and people were fighting over it.”

The popularity of the 3-D printers led Lehigh to purchase more. Over time, the lab grew into an extensive collection, one which now holds celebrity status in the powerhouse. But the metal printer is the new attraction — an imposing monster of a machine, partially divided from the rest of the building by glass walls, and complete with warning signs about its potential hazards. This kind of modern technology is what has brought Lehigh’s 3-D production potential to a whole new level.

“It’s amazing to see how much it’s really changed our capabilities as a university and the access that students and other faculty have to making projects real,” said Brian Slocum, the head manager of Wilbur design labs.

He mentioned the integrated project development course that is a requirement for mechanical engineers, material science and product design students.

“Five years ago, before we had as many printers as we (have), it took them a long time to get to the prototyping phase of the project,” Slocum said. “Bringing in just those small consumer-grade printers has allowed them to prototype in the very first semester, where typically they don’t even start to prototype until the second semester.”

The technology also helps students prepare for real jobs in the real world, even more so than they would in a traditional classroom setting. Experience with the printers brings students a step closer to the resources that they could potentially use in the future.

“It’s a much more reflective process of real, solid engineering, and I think the students find it much more interesting and much more real,” Verdonik said.

No longer do concepts learned in class have to stay abstract. Using the 3-D technology, students have the opportunity to put them to use and see the physical results of their learning.

While many universities have 3-D technology, the impact it has on learning is heightened by the “engineering school” stereotype that Lehigh carries.

Verdonik described some of the projects that he has seen come out of the 3-D printers. From cat-skeletons for a theater class to mounting parts in an electron microscope, the results are as varied as the studies of the students who create them. With this technology, students are able to break free from the constraints of a singular major, and can instead garner a more multidisciplinary education.

As the printers hum away in the background, producing three-dimensional items layer by layer, it’s hard not to marvel at this oasis of technological activity nestled in the heart of campus. And it’s hard to shake the feeling that to stand in Wilbur lab is to see what the future looks like.

Comment policy

Comments posted to The Brown and White website are reviewed by a moderator before being approved. Incendiary speech or harassing language, including comments targeted at individuals, may be deemed unacceptable and not published. Spam and other soliciting will also be declined.

The Brown and White also reserves the right to not publish entirely anonymous comments.

2 Comments

this is really amazing article. i really inspired by this article. thanks for sharing this amazing article.

3D printing is very popular nowadays. I am also a student and still learning how to do 3D printing at professional level, and your article help me a lot.